![]()

Source: Museum Of Solar Energy

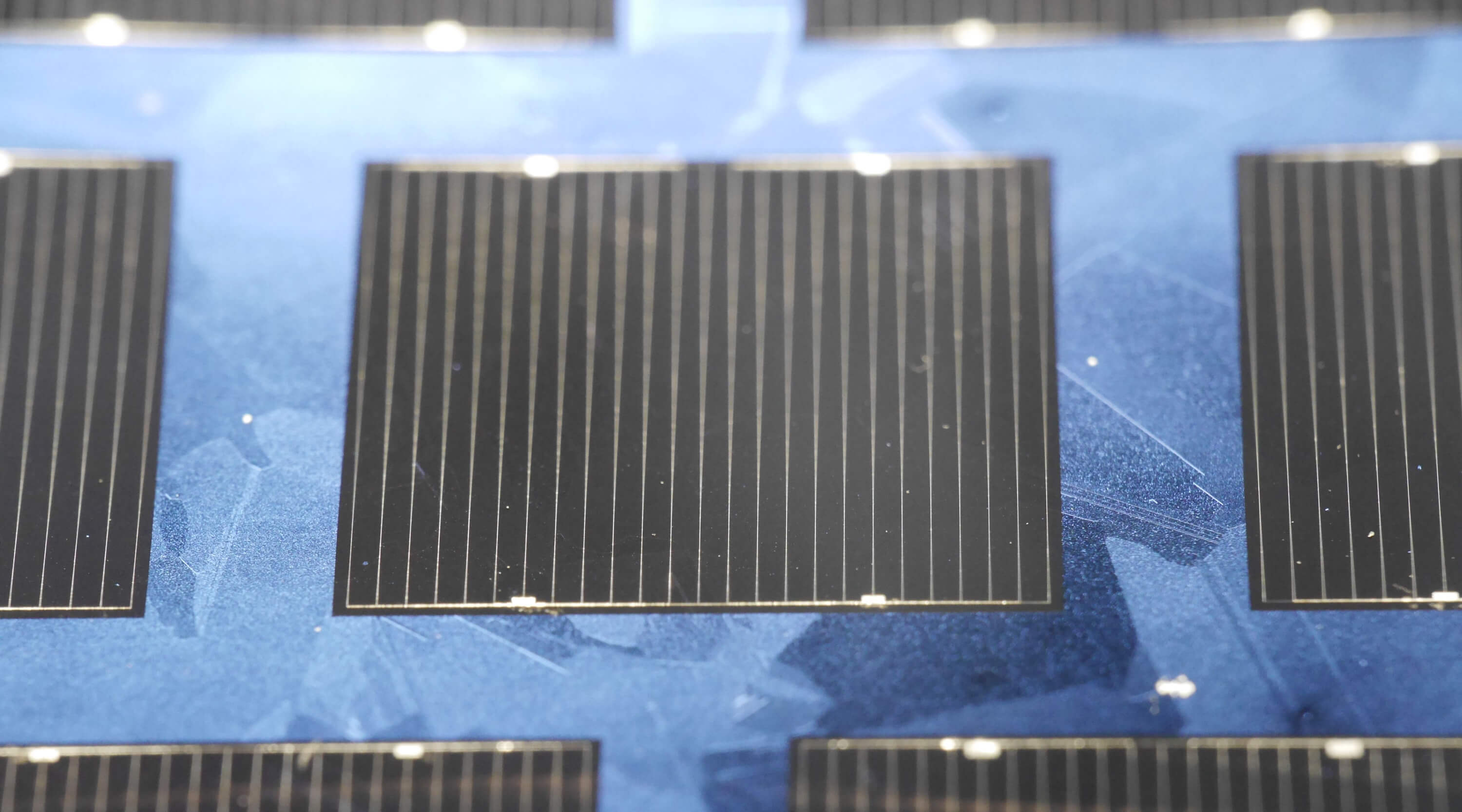

Understanding Multicrystalline Silicon for Solar Cells

When it comes to producing silicon for solar cells, there are two main techniques: single crystal and multicrystalline silicon. Multicrystalline silicon is favored for its simplicity and cost-effectiveness compared to single crystal silicon. However, the material quality of multicrystalline silicon is lower due to the presence of grain boundaries.

Effects of Grain Boundaries

Grain boundaries in multicrystalline silicon introduce localized regions of recombination, which reduces the overall minority carrier lifetime in the material. Additionally, these boundaries hinder carrier flows and can create shunting paths for current flow across the p-n junction, thereby decreasing solar cell performance.

Grain Size Matters

Traditionally, it was believed that larger grain crystals were ideal for multicrystalline silicon solar cells as they would have fewer grain boundaries. However, recent research has shown that smaller grains actually result in lower stress at the grain boundaries, making them less electrically active and reducing recombination. This has led to the adoption of a process that produces smaller grains, known as “high performance multi.”

Optimizing Grain Sizes

To minimize recombination losses at grain boundaries, multicrystalline silicon used in solar cells typically requires grain sizes of at least a few millimeters. This size allows single grains to extend from the front to the back of the cell, reducing resistance to carrier flow and decreasing the length of grain boundaries per unit of the cell. This optimized multicrystalline material is widely utilized in commercial solar cell production.

Source: Fraunhofer-Institut für Solare Energiesysteme ISE – Fraunhofer-Gesellschaft