Source: MDPI

The Emitter Diffusion Process in Solar Cell Manufacturing

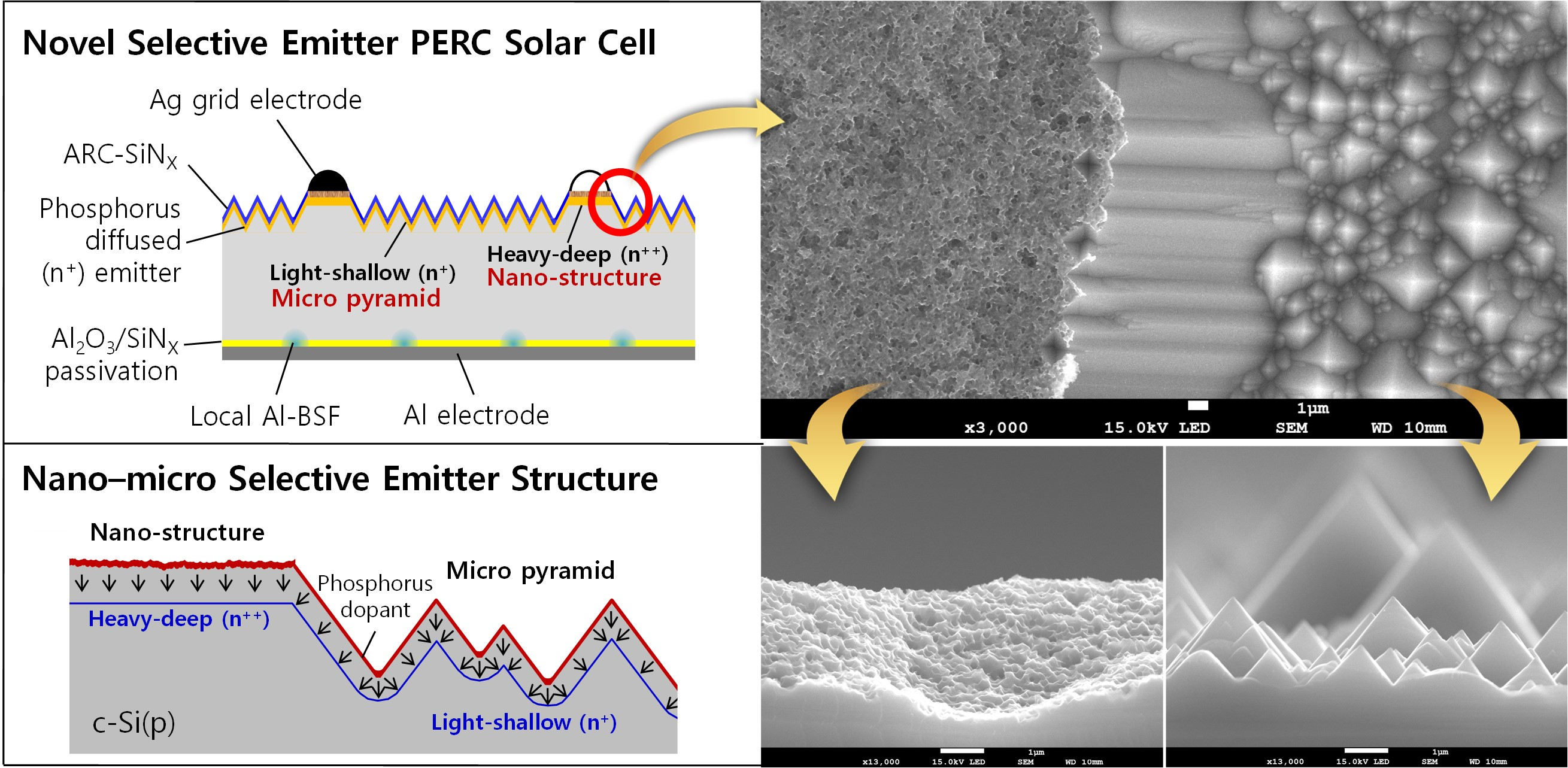

In the production of solar cells, the emitter diffusion process plays a crucial role in enhancing the cell’s efficiency. This process involves the introduction of specific dopants to create the desired electrical properties in the semiconductor material.

Process Description

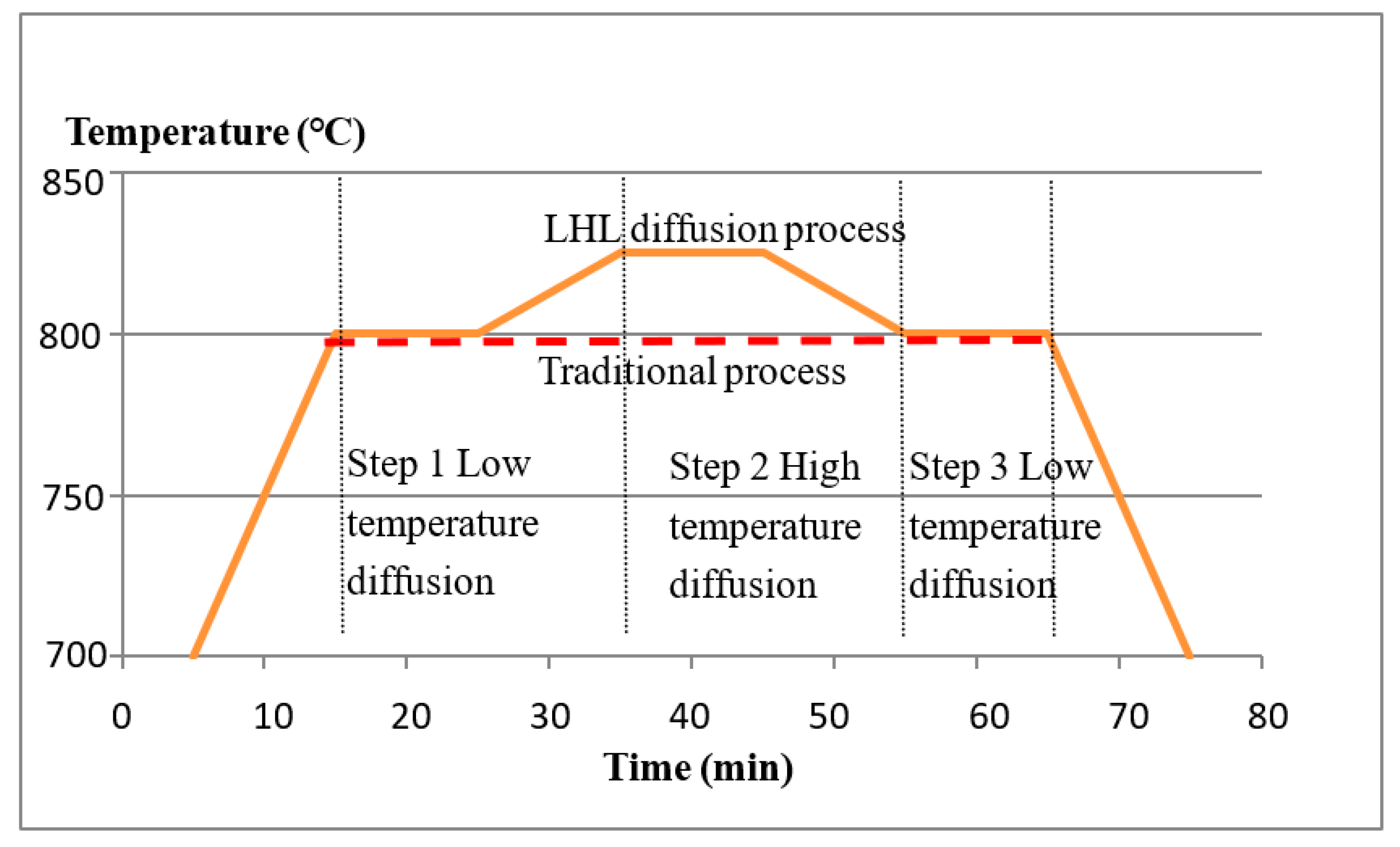

One common method of emitter diffusion is the application of a phosphorus-containing coating onto the surface of silicon wafers. These coated wafers are then subjected to high temperatures in a belt furnace. During this heat treatment, a small amount of phosphorus diffuses into the silicon surface, forming a layer with enhanced electrical conductivity.

Importance of Emitter Diffusion

The emitter diffusion process is essential for creating the necessary PN junction within the solar cell. This junction is crucial for facilitating the separation of photo-generated charge carriers, thereby enabling the conversion of solar energy into electrical power efficiently.

Enhancing Solar Cell Performance

By carefully controlling the emitter diffusion process, manufacturers can optimize the electrical characteristics of the solar cell. This optimization leads to higher efficiencies and improved overall performance of the solar panel.

Conclusion

Overall, the emitter diffusion process is a critical step in the manufacturing of high-quality solar cells. Through the precise introduction of dopants and controlled diffusion processes, solar cell manufacturers can produce efficient and reliable photovoltaic devices for renewable energy generation.

Source: MDPI